You know those thin metal strips used in construction, car parts, and appliances? Someone has to cut them from giant rolls of metal. That’s not a job you can do with regular scissors.

Metal arrives at factories in massive coils. We’re talking rolls that weigh as much as an elephant. These coils are usually way too wide for what manufacturers need. So they use specialized equipment to slice them lengthwise into narrower pieces.

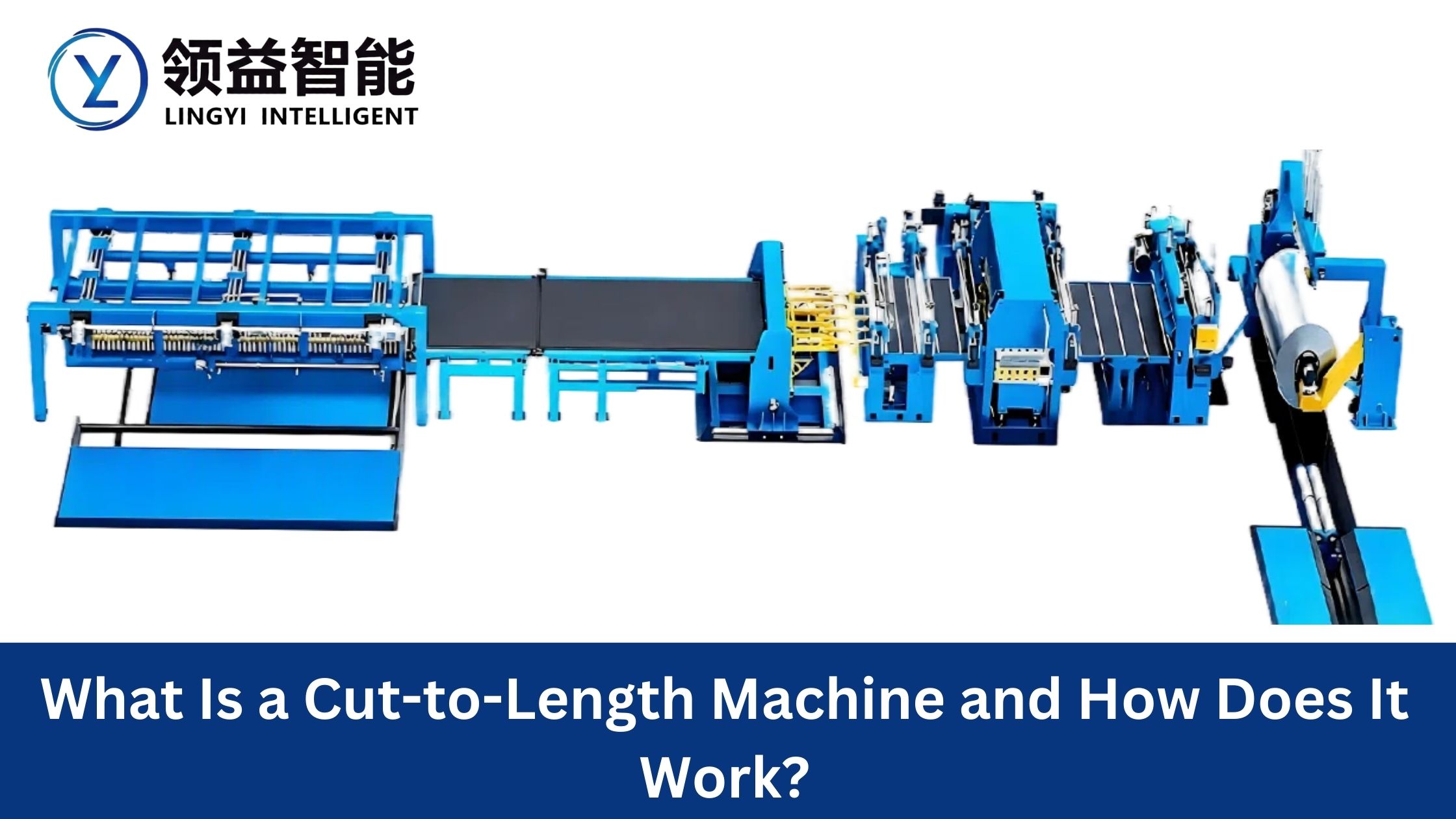

IMachine builds this type of equipment. Their machines turn one giant roll into dozens of perfectly measured strips. This blog explains how the whole system works and why factories depend on it.

What’s a Slitting Line Machine Anyway?

A slitting line machine cuts wide metal coils into skinny strips. Simple as that.

The machine handles different metals – steel, aluminum, copper, whatever comes in coil form. Factories need these machines because they can’t always buy metal in the exact width they want. Sometimes you have to cut it yourself.

The machine unwinds a large coil, straightens it, cuts it lengthwise, and then rewinds everything. All of this happens in one continuous line, like how pasta comes out of a pasta maker.

Did you know? Some of these machines can handle 30-ton coils. That’s literally the weight of six pickup trucks.

Breaking Down How It Works

Let me walk you through what happens inside a coil slitting line machine. It’s not as complicated as you might think.

Step One: Getting the Coil Started

Someone loads a massive metal coil onto the back of the machine. The unwinding section grabs it and starts feeding metal through. Speed control is huge here – go too fast, and you rip the metal, go too slow, and you waste time.

Step Two: Fixing the Bends

Rolled metal isn’t flat. It has memory curves and bends from sitting in coil form. The sheet leveling machine part fixes this problem.

Multiple rollers push and pull the metal in different directions. This releases the tension and flattens everything out. You can’t skip this step. Curved metal makes awful cuts.

Step Three: The Cutting Action

Now we get to the main event. The metal rolls through the slitting head where circular blades sit waiting.

Picture this:

- Blades on top and bottom line up like a pair of scissors

- Spacers sit between each blade set

- Those spacers control how wide each strip ends up

- Blades spin fast and slice right through

- Edge scraps fall off into bins

Did you know? These blades can slice through metal at 200 meters per minute. That’s faster than most people can drive in a school zone.

Step Four: Keeping Strips Apart

After the cut, you’ve got a bunch of strips traveling forward together. Special rollers guide each one on its own path. Otherwise, they’d tangle up worse than earbuds in your pocket.

Step Five: Rolling It Back Up

Each strip gets wound onto its own spool. The machine keeps the tension right so the coils stay tight. Loose coils are useless – they fall apart when you try to move them.

What These Machines Can Actually Do

Modern slitting line machines pack in some genuinely useful features.

The Tech Side

Computers run most of it now. You program in what you want, and the machine adjusts everything automatically. Need to switch jobs? Just load different settings instead of spending hours tweaking knobs and levers.

They handle different thicknesses, too. Some machines work with material as thin as heavy aluminum foil. Others power through steel plates several millimeters thick.

Swapping blades used to take forever. Now they pop in and out like battery cartridges. What took half a day now takes an hour.

Why Bother Getting One

Your scrap pile shrinks. Clean, accurate cuts mean less wasted metal ending up in the trash. That’s money you’re literally throwing away otherwise.Everything comes out the same. The machine doesn’t get tired or distracted. First cut of the day looks identical to the last cut.You only need one person running it. That frees up your other workers to do stuff that actually requires human brains.You can cut any width you dream up. No more begging suppliers to stock some oddball size. Just adjust the spacers and go.

Why Factories Love These Things

The advantages of using a slitting line machine in manufacturing go far beyond cutting metal.

The Money Part

Buying full-width coils costs way less per pound. It’s the same reason buying a whole chicken costs less than buying pre-cut pieces. When you do the slitting yourself, you keep that markup in your pocket.

Making What You Need, When You Need It

You don’t have to fill up your warehouse with fifty different strip sizes. Cut what you need for this week’s orders. The rest of the coil sits there waiting. Your storage space opens up, and your money isn’t tied up in inventory.

Controlling Quality Yourself

When you run your own slitting, you watch quality happen. IMachine equipment has sensors that catch problems on the spot. Bad edges, wrong widths, scratches – you see them immediately instead of finding out later from an angry customer.

Getting Weird Sizes

Need some random width that nobody stocks? Your slitting line machine doesn’t judge. Standard, custom, whatever – the machine cuts what you tell it to cut.

Did you know? Factories that run their own slitting typically save between 25% and 35% on material costs. That’s not pocket change.

Where You’ll Find These Machines

Precision parts manufacturing uses slitting line machines everywhere.

Car Factories

Auto plants use slitted metal for body panels, brake lines, wiring, and trim pieces. Each part needs exact dimensions, or it won’t fit right during assembly.

Building Stuff

Roofing, siding, air ducts, and metal framing – construction crews use slitted coils for all of it. The metal shows up already cut to the widths they need.

Appliance Manufacturing

Your refrigerator, washer, dryer, and stove – all of them have slitted metal inside: cabinet panels, brackets, trim. Everything needs specific widths.

Electronics

Circuit boards, shielding, connectors, battery parts. Electronics need crazy-accurate dimensions. Slitting machines deliver that level of precision.

Packaging Plants

Soup cans, bottle caps, food containers. They all start as metal coils that are slit before being stamped into their final shape.

Picking the Right Machine

Not every coil slitting line machine works for every job. You need to match the equipment to what you’re actually cutting.

What Metal Are You Cutting?

Soft materials like aluminum require sharp blades at specific angles. Hard stainless steel needs more rigid blades that cut differently. Use the wrong setup, and you’ll damage your material or wreck your blades in no time.

How Thick Is It?

Machines built for foil can’t touch a thick plate. Figure out what thickness you work with most often, then buy something rated to handle it plus a little extra.

How Much Volume?

Running a few coils a week? You can get by with a slower machine. Processing coils all day, every day? You need industrial equipment that won’t break down.

Got Enough Room?

These machines aren’t exactly compact. Measure your floor space before you order anything. Small models exist, but production-level equipment needs serious square footage.

Related Blogs:

- Precision Coil Slitting Line Machines for Modern Metal Processing

- Top 5 Things to Evaluate When Choosing a Slitting Line Machine

Taking Care of Your Machine

Your slitting line machine won’t run forever without maintenance. Here’s what you need to do.

Every Single Day:

- Check if the blades are still sharp

- Look for worn spots on rollers

- Make sure everything’s oiled up

- Test the tension controls

Once a Week:

- Clean out all the metal shavings

- Check the electrical stuff for loose connections

- Look at the hydraulic lines and fluid

- Measure some finished strips to check quality

Monthly Stuff:

- Really examine those blades closely

- Check belts and chains in the drive system

- Test every safety feature

- Recalibrate measurements if they’re drifting

Skip maintenance, and you’ll pay for it later with breakdowns and repairs.

Wrapping This Up

Slitting line machines do one thing really well. They take oversized metal coils and turn them into perfectly cut strips. The engineering behind it is clever, even if the concept sounds simple.These machines are working right now, making parts for products you’ll use today. Your car has slitted metal in it. So does your fridge. The building you’re in right now, too.If you work in manufacturing, knowing how slitting works helps you make smarter choices about equipment and materials. The process makes sense once someone walks you through it.

IMachine keeps making better equipment every year. The technology gets more precise and more efficient. That benefits everyone who uses metal parts, which is basically everyone.Ready to enhance your metal processing capabilities? Getting the right slitting line equipment changes everything about how your shop runs. Look into what actually fits your needs, not what sounds impressive in a sales pitch. The right machine pays for itself.

Frequently Asked Questions:

Q1. What kind of metal can I run through a slitting line machine?

You can run steel, stainless, aluminum, copper, brass, galvanized – basically anything that comes in coil form. Thickness ranges from super-thin foil around 0.1mm to plates a few millimeters thick. Your coil slitting line machine handles whatever falls in its rated range.

Q2. Will a slitting line machine actually make my shop more efficient?

Yeah, it will. The slitting line machine does everything automatically, from unwinding to rewinding. That means better precision parts manufacturing because you’re not relying on people to make manual cuts: less waste, better accuracy, faster production.

Q3. Why would I buy one instead of just cutting metal by hand?

Speed and accuracy. The advantages of using a slitting line machine in manufacturing are obvious – it cuts at 200 meters per minute, stays accurate within 0.1mm, needs way less labor, wastes almost nothing, and handles coils you couldn’t even move by hand.

Q4.Does it come with a leveling section, or do I add that separately?

Most coil slitting line machines these days have the sheet leveling machine section built right in. You need that leveling to get rid of coil memory before you cut. Otherwise, your strips come out wavy and bent.

Q5.How much money does this thing actually save me?

A slitting line machine saves you money in a bunch of ways. If you buy cheaper full-width coils, you waste less material, you cut inventory costs by not stocking pre-cut sizes, and you need fewer workers. Most places see real savings quickly.