If you buy steel or aluminum in coils, you still need flat sheets, actually, to build things. Your laser table needs sheets. Your press needs sheets. Your fabrication team needs sheets that sit flat and measure right.

That is exactly what a cut-to-length machine does. It unwinds a coil, flattens it, measures the length you choose, and cuts clean sheets you can stack and move.

Here’s the thing: when the line is set up well, you waste less material, and you spend less time fixing bad sheets. When it is set up poorly, you get length errors, waves, burrs, and piles that do not stack straight. This is why precision equipment manufacturing matters in these lines.

Objective

To help you understand what a cut-to-length machine is, how it works step by step, what affects cut-to-length machine speed, and the difference between a cut-to-length line and a slitting line.

Key Takeaways

- A cut-to-length machine converts coil into flat sheets at your chosen length.

- Flatness comes mainly from the leveler settings, not the shear.

- Cut-to-length machine speed depends on thickness, accuracy requirements, and stacking limits.

- The difference between a cut-to-length line and a slitting line is the output: sheets vs. narrower coils.

- Good cut-to-length machine maintenance protects accuracy, safety, and uptime.

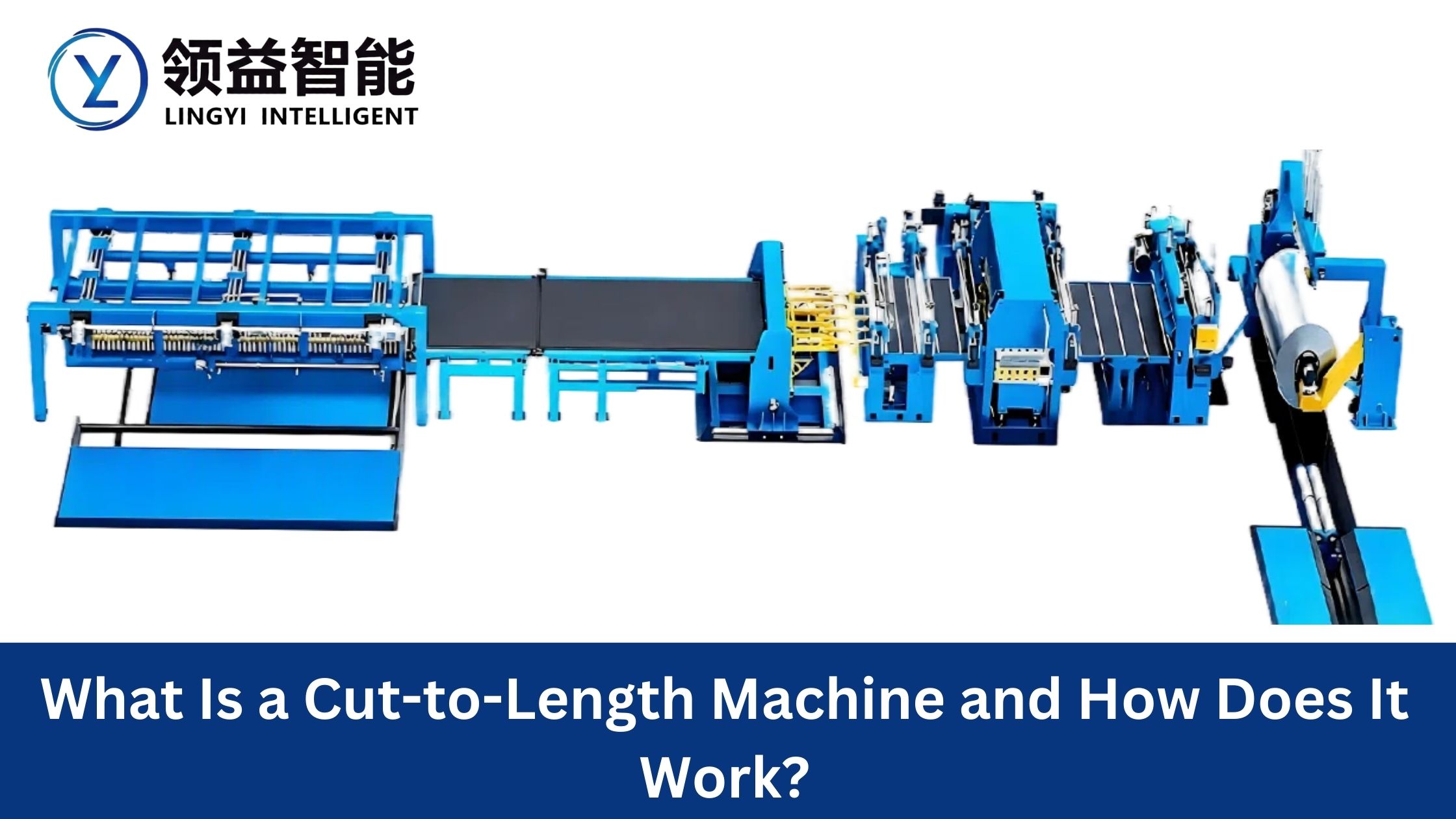

Industrial Cut-to-Length Machine Overview

An industrial cut-to-length machine is a coil processing line that produces flat sheets. You feed a coil at one end, and you get stacked sheets at the other.

You will see this equipment in places like:

- steel service centers

- appliance and HVAC plants

- auto parts suppliers

- construction material shops

- general metal fabrication facilities

If your business needs consistent sheet sizes all day, a cut-to-length machine is often the most direct way to achieve them.

Did you know coil material can “remember” its shape even after cutting? That’s why proper leveler tuning is often the heart of a cut-to-length machine.

What a Cut-to-Length Machine Produces

A cut-to-length machine produces flat sheets that match the length you set in the controls. You can cut one length all day or run a mix of lengths in batches.

Typical output includes:

- flat sheets at programmed length

- bundled stacks for forklift handling

- counted sheets per stack when the stacker supports it

What this really means is you can move from coil storage to sheet production without relying on manual measuring and cutting.

How a Cut-to-Length Machine Works Step by Step

Let’s break it down in the order in which material flows through the line.

Step 1: Uncoil with controlled tension

The coil mounts on an uncoiler. The uncoiler feeds the strip forward while maintaining stable tension. Stable tension helps your length accuracy and helps prevent wandering.

Step 2: Guide and align the strip

Side guides keep the strip centered. If the strip drifts, you can end up with edge damage, bad tracking through the leveler, and messy stacks.

Step 3: Level the strip to get it flat

The leveler uses rollers to remove the coil set and waves. This is a key step. If leveling is off, you can cut the correct length and still end up with sheets that do not sit flat.

Step 4: Feed and measure the length

Feed rolls move the strip forward. A measuring device tracks the length as it travels. Most lines use an encoder and sensor system to measure accurately.

Step 5: Cut the sheet

A shear cuts the strip when the target length is reached. Some lines stop to cut. Others use a flying shear that cuts as the strip moves.

Step 6: Stack and count sheets

The sheet exits to a run-out table and then to a stacking system. Good stacking matters more than many people expect, because poor stacking creates damage and slows handling later.

Main Parts of a Cut-to-Length Machine

A typical cut-to-length machine line includes:

- Uncoiler to hold and unwind the coil

- Pinch rolls to grab and feed the strip reliably

- Leveler to flatten the strip and remove coil memory

- The feeder to drive the strip forward at a steady speed

- Length measuring system to track exact travel

- Shear to cut sheets to length

- Run-out table to support the sheet after cutting

- Stacker to collect sheets into neat piles

In precision equipment manufacturing, minor quality differences in rollers, bearings, guides, and sensors show up as real production problems. You see them as inconsistent lengths, poor flatness, and extra scrap.

IMachine is one name you may see in this space, but the bigger point is understanding what each part does and what it must do reliably.

Cut to Length Machine Speed and What Controls It

People often ask for a single number for the cut-to-length machine speed. In real production, speed is a range, not a fixed value.

Here are the main things that control the cut-to-length machine speed:

- Material thickness and strength: Thicker, stronger materials usually run slower.

- Flatness requirements: Tighter flatness needs more careful leveling. That can reduce speed.

- Length tolerance: A tighter tolerance often means more controlled feeding and cutting.

- Cut method: stop-to-cut lines behave differently from flying shear lines.

- Stacking and handling: if stacking cannot keep up, the whole line slows down.

A practical way to think about speed is this: the best speed is the fastest speed that still gives flat sheets that measure right and stack cleanly.

Difference Between Cut-to-Length Line and Slitting Line

The difference between a cut-to-length line and a slitting line is the finished product.

- A cut-to-length machine produces flat sheets.

- A slitting line machine produces narrower coils.

Both start from a wide coil, but they serve different downstream jobs.

If your next step is laser cutting, bending, or stamping sheets, you usually want a cut-to-length machine. If your next step is roll forming or making tubing from strips, you usually want a slitting line machine.

Slitting Line Machine Basics

A slitting line machine uses rotary knives to cut the coil width into multiple narrow lanes. Then it rewinds those lanes into smaller coils.

A typical slitting flow includes:

- uncoiling

- guiding and tension control

- slitting with circular knives

- separating lanes

- rewinding into multiple coils

If your customers order narrow strip coils or your production needs strip coils for roll forming, a slitting line machine is often the right tool.

Difference between cut to length line and slitting line in one view

| Item | Cut to length machine | Slitting line machine |

| Output | Flat sheets | Narrow coils |

| Cutting tool | Shear | Rotary slitting knives |

| Best used for | Sheet-based fabrication | Strip-based forming |

| Main quality focus | Flatness and length | Width accuracy and edge control |

| Common bottleneck | Stacking | Rewinding tension |

Cut to Length Machine Maintenance That Actually Prevents Problems

Good cut-to-length machine maintenance is not just cleaning. It is the difference between steady output and constant troubleshooting.

Here are the checks that usually matter most.

Daily checks

- Remove debris around rollers and guides.

- Check lubrication points and oil levels.

- Look for unusual marks on the strip that could mean roller damage.

- Confirm sensors and the measuring wheel area are clean.

Weekly checks

- Inspect shear blades for wear and edge damage.

- Check guide alignment and fasteners.

- Watch stacking performance and timing, because mis-stacks often signal setup drift.

Monthly or planned checks

- Verify length accuracy with measured test sheets.

- Check leveler rolls for wear patterns.

- Inspect hydraulic or pneumatic systems if your line uses them.

- Clean electrical cabinets and check connections for heat or looseness.

Suppose you want a stable cut-to-length machine speed; maintenance matters. Wear and poor setup often force operators to slow the line just to keep it under control.

Conclusion

A cut-to-length machine is a practical way to turn a coil into sheets you can use immediately. You uncoil, level, measure, cut, and stack. Once you understand that flow, it becomes easier to spot where problems come from and what to adjust first.

If you are planning a line or improving an existing one, focus on three things you can control: leveling quality, measurement accuracy, and a maintenance routine that you actually follow. IMachine is one brand you may be reviewing, but your best results come from matching the line to your material, your tolerance needs, and your real production goals.

Frequently Asked Questions:

Q1.What is a cut-to-length machine used for in coil processing?

A cut-to-length machine converts a coil into flat sheets of a set length. You use it when your downstream work needs sheets that measure right and sit flat.

Q2.How does a cut-to-length machine work in simple steps?

A cut-to-length machine uncoils the strip, levels it, measures its travel length, and cuts it with a shear. The sheets are then moved to a table and a stacker for handling.

Q3.What is the difference between a cut-to-length line and a slitting line for production planning?

The difference between a cut-to-length line and a slitting line is the finished form. Cut to length makes sheets. Slitting makes narrower coils that are rewound for strip use.

Q4.What factors affect cut-to-length machine speed during daily runs?

Cut-to-length machine speed changes based on thickness, material strength, flatness needs, tolerance settings, cut method, and how fast the stacker can keep up.

Q5.What does cut-to-length machine maintenance usually include?

Cut-to-length machine maintenance usually includes cleaning and lubricating rollers, inspecting shear blades, checking measurement sensors, verifying length accuracy, and monitoring leveler wear.

Q6.When should you choose a slitting line machine over a cut-to-length machine?

Choose a slitting line machine when you need narrow strips rewound into coils, such as for roll-forming, tubing, or strip-stamping lines.

Q7.Why does precision equipment manufacturing matter in a cut-to-length machine line?

In precision equipment manufacturing, tighter build quality in rollers, guides, and measuring systems helps your cut-to-length machine hold length and flatness more consistently across long runs.

Q8.How can you reduce scrap on a cut-to-length machine?

To reduce scrap on a cut-to-length machine, keep guides aligned, tune leveling for flatness, maintain sharp shear blades, confirm encoder accuracy, and keep feeding tension steady.