When metal flatness defines product quality, only advanced solutions can deliver consistent results. Our Hydraulic Leveling Machine is engineered for Indian manufacturers who demand accuracy, speed, and stability in high-volume sheet processing.

Seamlessly working with a CNC Leveling Machine ensures smooth production flow, reduced material stress, and flawless sheet surfaces. From automotive panels to heavy plates and precision components, it delivers reliable flatness with minimal operator intervention. For lighter or custom jobs, our Manual Leveling Machine and automated CNC systems handle ultra-precision requirements.

| Model | LYC10 | LYC20 | LYC30 | LYC40 | LYC50 | LYC60 | LYC80 | LYC100 | LYC120 |

|---|---|---|---|---|---|---|---|---|---|

| Roller Diameter | 10 | 20 | 30 | 40 | 50 | 60 | 80 | 100 | 120 |

| Roller Number | 31 | 25 | 23 | 21 | 19 | 19 | 19 | 19 | 19 |

| Level Speed | 10m/min | 10m/min | 10m/min | 10m/min | 10m/min | 10m/min | 10m/min | 10m/min | 10m/min |

| Pass Width | <150 | <200 | <1500 | <1500 | <1500 | <1500 | <2000 | <2000 | <2000 |

| Thickness Range (Q235) | 0.05–0.8 | 0.08–1.0 | 0.3–1.2 | 0.6–3.0 | 0.8–4.0 | 1.0–6.0 | 2.0–8.0 | 3.0–10.0 | 4.0–12.0 |

| Shortest Workpiece | 20mm | 40mm | 60mm | 80mm | 100mm | 120mm | 150mm | 180mm | 200mm |

| Optional | Four/Six-Layers | Conveyor Tables | Manipulators | Support Roller Adjustment | Automatic Detection Platform | ||||||||

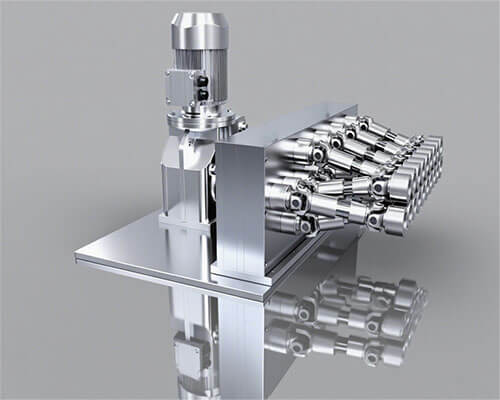

Equipped with an Automatic hydraulic leveling system, this machine adjusts pressure in real time. Servo-controlled hydraulics ensure uniform flatness without manual recalibration for Indian high-volume workshops.

Our Industrial hydraulic leveling machine features a reinforced frame, hardened rollers, and a vibration-resistant design, delivering reliable performance under heavy loads and continuous operation in demanding Indian factories.

This Precision sheet leveling equipment handles steel and aluminium sheets from 0.3 mm to 80 mm. Multi-roller technology removes warping, producing stable, flat sheets for welding, cutting, and forming.

With flatness accuracy up to 0.3 mm per metre, this Sheet leveling machine ensures consistent quality, smoother surfaces, reduces downstream errors, and improves fitment for high-precision manufacturing.

The intelligent pressure feedback system lowers energy use by 30%, making this low-cost hydraulic leveler efficient, reducing operational costs, material waste, and improving ROI for Indian manufacturers.

Automatic feeding and fast roller adjustment boost single-shift output by nearly 40%. This increases throughput while reducing downtime, making it ideal for high-volume Indian production lines.

Body panels, chassis components, and trim with consistent flatness.

Thick plates and high-strength steel leveled for machinery or infrastructure.

Flat sheets ready for precise bending and enclosure assembly.

Deformation correction in welded or transported plates.

Stress-free sheets for CNC machining, laser cutting, or robotic welding.

Across industries, this machine reduces rework, lowers scrap, and increases finished-part quality.

For workshops with mixed production, this hydraulic machine complements a Manual Leveling Machine for low-volume or custom jobs. It also works alongside automated CNC systems to deliver pre-leveled sheets ready for ultra-precision operations. This ensures a seamless workflow across your production ecosystem.

Leading precision equipment parts manufacturers rely on our leveling machines to maintain strict tolerances. Uniform sheets improve tool life, reduce material stress, and ensure high-quality components, whether for industrial assemblies or automotive applications.

Adding our Industrial hydraulic leveling machine improves workflow efficiency:

As a leading Hydraulic leveler manufacturer, we deliver machines designed for Indian industrial challenges. Rugged, reliable, and cost-effective, our solutions come with expert consultation, installation support, and responsive after-sales service.

Direct supply from our Hydraulic leveling machine factory ensures competitive pricing, transparency, and rapid delivery. We also provide customised configurations to match your production requirements.

Pair your hydraulic leveling machine with other precision tools for a complete workshop ecosystem:

Together, these machines create a streamlined production chain, improving output, efficiency, and product quality.

Invest in precision, speed, and durability with our Hydraulic Leveling Machine. Designed to integrate seamlessly with a CNC Leveling Machine, it is the wise choice for Indian manufacturers aiming for consistent quality, lower costs, and scalable growth.Upgrade your production and achieve flawless flatness with the best hydraulic leveling machines on the market.

As a technology and market leader in leveling technology, Lingyi provides the world’s widest range of high-performance precision roller leveling machines. These products range from straightening machines for thin or complex parts to straightening machines for thick plates and even armored steel materials. In the field of shipbuilding, Lingyi has innovatively developed a flattening solution tailored to the characteristics of the shipbuilding industry to address the challenge of flattening large ship hull plates. This solution successfully resolves deformation issues caused during welding and transportation, ensuring the overall structural strength and navigational stability of the vessel. Additionally, in the field of sheet metal flattening processing, Lingyi has accumulated extensive experience in flattening sheet metal parts made from various metal materials, different thickness specifications, and complex shapes. The company can provide customized flattening services tailored to customers’ specific needs, meeting the diverse demands of the market.

It removes warping and internal stress from metal sheets, ensuring flat, stable surfaces for cutting, welding, and CNC machining.

It adjusts hydraulic pressure in real time, delivering uniform flatness up to 0.3 mm per metre without manual adjustment.

It levels steel and aluminium sheets from 0.3 mm to 80 mm using a multi-roller precision leveling system.

Yes, automatic feeding and fast adjustments boost output by up to 40%, making it ideal for continuous industrial use.

Yes, it complements manual leveling machines for small jobs and CNC systems for high-precision production.

Would you like to request additional information about Lingyi Intelligent Machines and Engineer services?

We are happy to assist you.

Copyright © 2025 Lingyi Engineering Team