Straightening Machines for Smooth, Flat Metal Finishing

In precision manufacturing, flatness is more than just a cosmetic feature—it’s a performance necessity. Whether you’re producing components for the automotive, aerospace, construction, or electronics industries, even a minor warp or internal stress can lead to failure down the line. That’s why integrating a straightening machine into your operation isn’t optional—it’s essential.

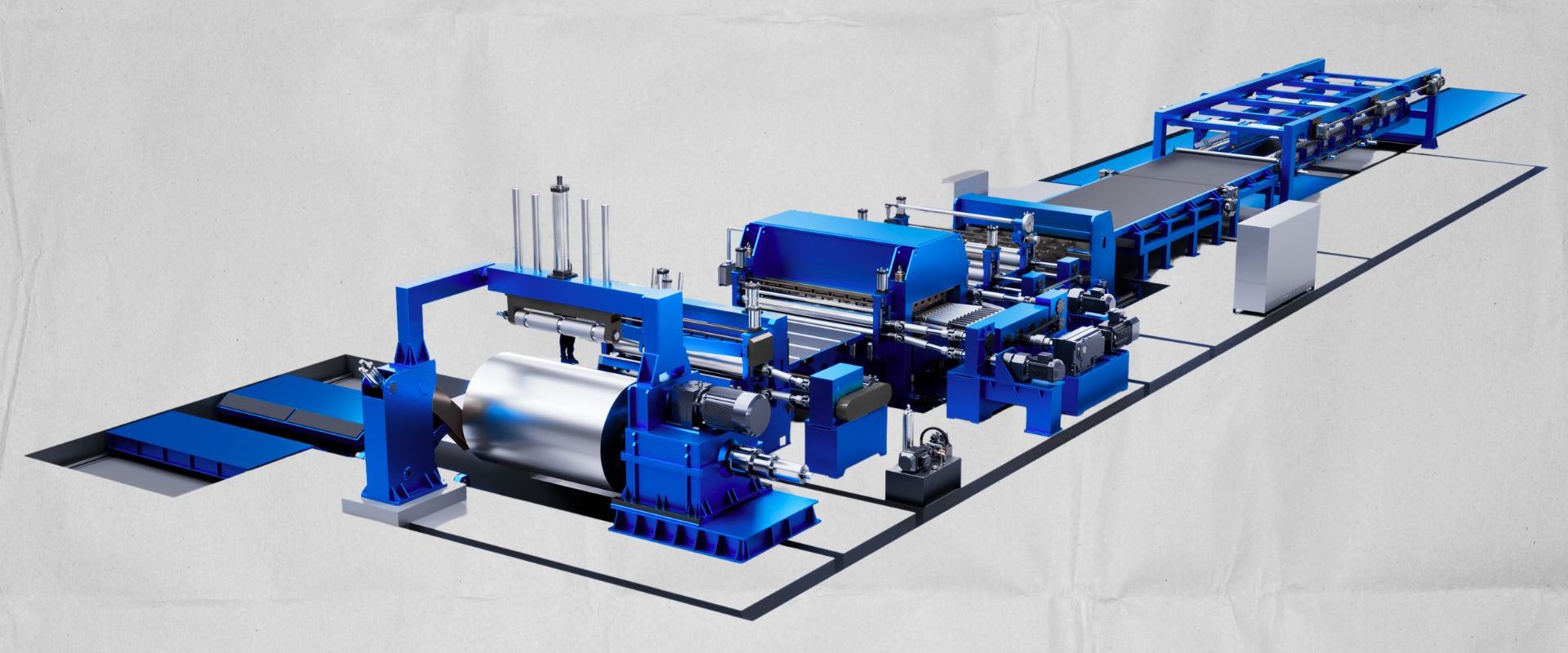

Today’s advanced cut-to-length machine lines do more than just cut—they straighten, level, and prepare metal for further processing. Combining this with sheet leveling machine technology enables manufacturers to meet strict tolerances while boosting productivity and reducing waste.

Understanding the Role of Straightening Machines in Metal Processing

This machine plays a critical role in post-coil processing. After coiled metal is unwound, it often contains curvature, waves, or residual stress. A straightening system applies controlled force to remove these issues, resulting in sheets that are flat, smooth, and stress-free—ideal for downstream operations such as welding, stamping, or CNC machining.

These machines are often integrated with metal cut to length machine systems, which allow operators to automatically set desired lengths, feed metal through straighteners, and cut precisely, all in one seamless process.

Core Advantages of Using Straightening Machines

Let’s break down why these machines are a game-changer in high-demand industrial environments:

1. Micron-Level Precision

Modern straightening machines offer extremely fine control over pressure and alignment. This is essential for handling high-strength alloys or thin sheets that can easily distort.

2. Fast Setup and Operation

Quick-change tooling and automated PLC controls ensure faster cycle times and repeatable accuracy, even for high-volume production.

3. Flexible Material Handling

These machines can process a wide variety of metals, from aluminum to stainless steel, and accommodate coil widths up to 2,500 mm and thicknesses from 0.3 to 12 mm. Custom setups are available to handle unique project requirements.

4. Seamless Integration with Other Machines

These often work in tandem with sheet cut to length equipment, automatic manufacturing machines, and Burr Removing Machines, forming a fully automated production line with minimal manual intervention.

Different Types of Straightening Machines

Choosing the right configuration depends on your production goals, the type of material, and your budget. Here are the most common types:

1. Manual Levelers

Perfect for short runs or custom jobs. They allow operators to adjust settings for hands-on control and flexibility manually.

2. CNC Levelers

These are ideal for high-volume operations requiring repeatable results. Programmable memory stores job-specific data, enabling faster transitions between tasks.

3. Hydraulic Levelers

Built for heavy-duty applications, these machines handle thick plates and high-tensile materials with ease, using powerful hydraulic force for deep straightening.

Each model delivers consistent results that support downstream processes, such as precision cutting, folding, stamping, and laser operations.

Straightening Machines in Action: Key Industry Applications

Whether it’s in metal fabrication, appliance manufacturing, shipbuilding, or HVAC production, these machines serve a vital purpose.

Automotive & Aerospace: For flat body panels and tight-tolerance components

Construction: To ensure load-bearing sheet metal meets safety standards

Electronics: For delicate, thin sheets needing micron-level accuracy

General Manufacturing: To streamline production with fewer rejects and rework

The Synergy of Straightening and Cut-to-Length Systems

In a modern facility, the power of a steel coil cutting machine combined with a straightening machine creates a high-efficiency line. These systems allow automatic feeding, straightening, length measurement, and cutting—all managed by smart PLC systems.

The Automatic cut to length line streamlines the entire operation, from coil loading to stacking flat sheets. This eliminates human error, speeds up production, and delivers consistent quality every time.

Innovations That Elevate Performance

Lingyi Engineering’s machines are engineered with both precision and practicality in mind. Some standout features include:

Automated Control Systems: For intelligent diagnostics and consistent pressure control

Robust Construction: Designed for high-load environments with durable frames and components

Safety First: Integrated guards, emergency stops, and intuitive controls keep your staff safe

Smart Interface: User-friendly touch panels simplify operation and training

When paired with CNC Leveling Machines and automatic manufacturing machines, these setups deliver unmatched productivity and flexibility. The result? Reliable production that meets the demands of modern manufacturing.

What to Consider Before Choosing a Straightening Machine?

Before selecting a machine, consider the following factors:

Material Type & Thickness: Choose the right force capacity for your metal type.

Output Requirements: Estimate the volume and speed needed to match production targets.

Automation Needs: Determine whether manual control or PLC automation suits your workflow.

Space Constraints: Measure available floor space and consider modular setups.

Budget & ROI: Balance upfront cost with long-term productivity and quality gains.

Investing in the right straightening machine pays off through reduced waste, fewer defects, and faster throughput.

Beyond Flat Sheets: Enhancing Overall Production Quality

A levelling machine not only perfects sheet flatness but also lays the foundation for a smooth, efficient operation. Combined with burr removing machines, sheet leveling machines, and cut to length machines, it forms a complete solution for modern fabrication.

This synergy enhances:

Material consistency

Component fit

Aesthetic appeal

Operational reliability

More importantly, it reduces downtime, manual intervention, and rework, driving overall efficiency.

Bringing it All Together

To stay competitive in today’s fast-paced manufacturing world, you need equipment that delivers precision, flexibility, and automation. A straightening machine is no longer just a useful add-on—it’s a vital part of achieving flat, accurate, and defect-free sheets.

Whether you’re processing thin aluminum for electronics or thick steel plates for heavy-duty applications, integrating straightening with metal cut to length machine systems ensures a higher standard of quality and speed.

With micron-level precision, automated controls, and durable construction, these machines help manufacturers maintain quality, optimize production, and reduce costs.

You can explore high-performance solutions and configurations tailored to your needs at Lingyi Engineering Group.

Frequently Asked Questions

Q1. What is the main function of a straightening machine?

A straightening machine removes curves, waves, and internal stress from metal sheets after coil processing. This results in smooth, flat, and stress-free metal for further use.

Q2. Which industries benefit most from straightening machines?

Industries like automotive, aerospace, construction, and electronics rely on flat, precise metal sheets. These machines ensure component accuracy, safety, and performance.

Q3. What types of straightening machines are available?

Common types include manual levelers for short runs, CNC levelers for automated precision, and hydraulic models for heavy-duty straightening. Each suits different production needs.

Q4. How do straightening machines integrate with other equipment?

They often work alongside cut-to-length and burr removing machines in automated lines. This boosts efficiency, reduces manual work, and ensures consistent quality.

Q5. What should I consider before buying a straightening machine?

Key factors include material type, sheet thickness, desired output volume, automation level, space availability, and long-term ROI. Choosing the right machine enhances overall productivity.