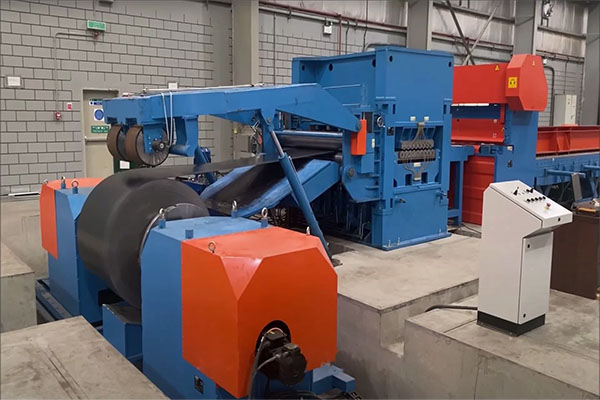

Lingyi’s Cut-To-Length (CTL) machines guarantee perfectly sized sheets from coils, delivering outstanding performance every time. They are the ideal solution for industries requiring high-volume, precise cutting. They maximise productivity by reducing waste and improving the efficiency of material handling.

| Model | Thickness Range | Width (mm) | Weight | Working Type | Stacking | Line Speed |

|---|---|---|---|---|---|---|

| CTL01 | 0.3–2.0mm | 1300 / 2000 | 10 / 15 / 20 | Flying / Rotary-Shear | 3000 / 6000 | 60 m / min |

| CTL02 | 0.5–3.0mm | 1300 / 2000 | 10 / 15 / 20 | Flying / Rotary-Shear | 3000 / 6000 | 50 m / min |

| CTL03 | 0.8–4.0mm | 1300 / 2000 | 10 / 15 / 20 | Flying / Rotary-Shear | 3000 / 6000 | 40 m / min |

| CTL04 | 1.0–6.0mm | 1300 / 2000 | 10 / 15 / 20 | Flying / Rotary-Shear | 3000 / 6000 | 50 m / min |

| CTL05 | 2.0–8.0mm | 1300 / 2000 | 10 / 15 / 20 | Flying / Rotary-Shear | 3000 / 6000 | 30 m / min |

| CTL06 | 6.0–25.0mm | 1300 / 2000 | 10 / 15 / 20 | Flying / Rotary-Shear | 3000 / 6000 | 26 m / min |

We specialise in the automotive, appliance and steel service industries. Lingyi’s Cut-to-Length systems are the ideal solution for manufacturers requiring precise cutting of coils into fixed lengths. They are perfect for cutting both thin and thick metals, from aluminium sheets to heavy-duty steel plates.

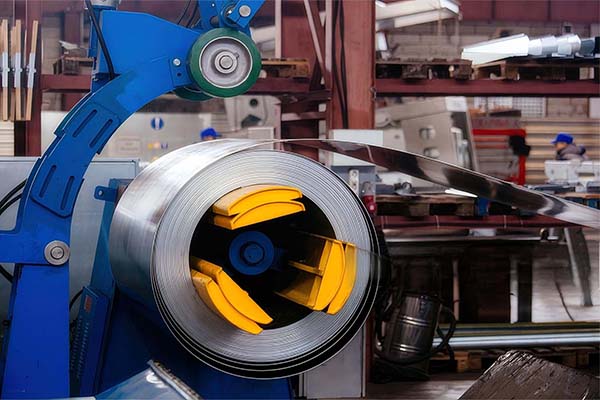

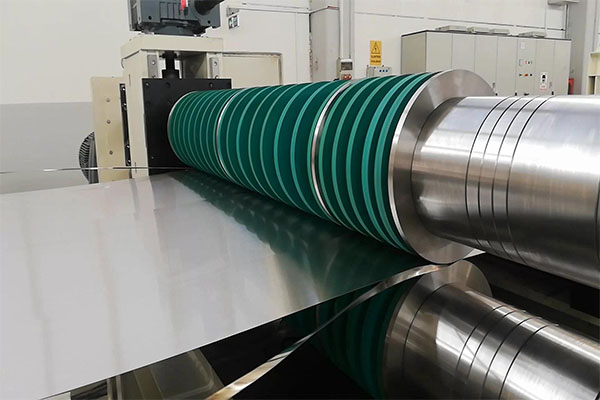

The Cut to Length Line consists of a decoiler, a servo feeder with straightener, a shear system and stacking units.

With over ten years’ experience in metal processing, we specialise in fixed-length cutting and slitting line installation. We have completed over 20 benchmark projects for leading companies in the automotive, home appliance, sheet metal and construction steel sectors. Our rigorous quality control process ensures precision at every stage of every project, adhering to international testing standards from equipment selection to installation. We are committed to the success of our customers, enhancing their experience through regular follow-ups, technological upgrades and a rapid 24/7 response.

Would you like to request additional information about Lingyi Intelligent Machines and Engineer services?

We are happy to assist you.

Copyright © 2025 Lingyi Engineering Team