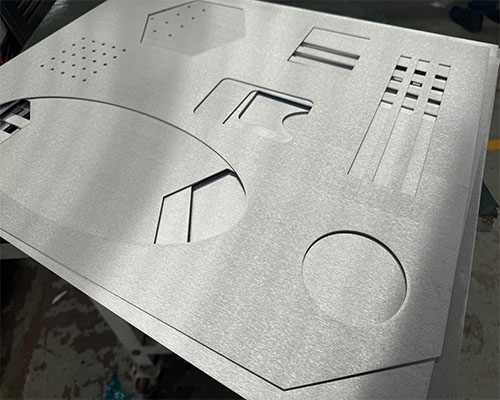

Subsequent to the processes of flame cutting, plasma cutting and high-power laser cutting of medium-thick plates, the removal of slag and burrs is undertaken, along with micro-rounding processing. The first station employs a high-quality alloy elastic end-face D-type slag removal head. The second station has the capacity to be equipped with either a D-type or a G-type narrow sandbelt burr removal grinding head. The third station is equipped with a dual-grinding belt head, achieving nearly 100% slag and burr removal efficiency. This machine exhibits a low level of consumable usage, and its operation is straightforward. It functions silently and does not emit dust, thus obviating the need for manual labour in the process of slag removal.

We meticulously pay attention to every minute detail in our work and consistently strive for nothing short of perfection. This unwavering commitment is not merely a superficial pursuit of flawlessness; it is deeply ingrained in our organizational ethos, guiding each action and decision. Our team members, each an expert in their respective fields, collaborate seamlessly, bringing diverse perspectives to the table and ensuring that every aspect of the project is thoroughly examined. We understand that even the smallest oversight can have far – reaching consequences, so we have established rigorous quality control measures at every stage of the process. We are constantly seeking new ways to innovate and enhance our processes, staying ahead of the curve in an ever – evolving industry. By maintaining this high standard of work, we are confident in our ability to tackle any challenge that comes our way and continue to exceed expectations in all our endeavors.

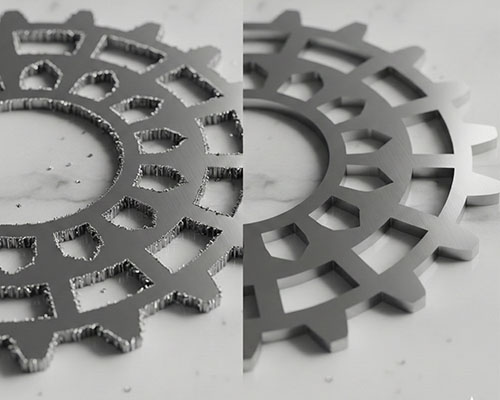

We are thrilled to share that we have successfully removed all burrs and sharp edges from parts using state-of-the-art deburring technology and equipment. This ensures that the parts meet the highest safety and functional standards, which our customers have really appreciated. The results speak for themselves: the part performance and service life have significantly improved. In a polishing project for a luxury watch manufacturer, we used professional polishing agents and special processes to create a stunning mirror-like finish. This has highlighted the exquisite design, and the customers have been absolutely delighted with the finished product, which has driven sales growth. For a project with an aerospace component supplier, we performed chamfering to eliminate sharp angles and reduce stress concentration. The precise process was absolutely key to making sure the parts met the stringent standards required, and the client was thrilled with our attention to detail and surface treatment. This meant we were able to secure a contract with a major manufacturer. These cases are a testament to our unparalleled expertise in deburring, polishing, and chamfering services, and we are dedicated to surpassing your expectations.

Would you like to request additional information about Lingyi Intelligent Machines and Engineer services?

We are happy to assist you.

Copyright © 2025 Lingyi Engineering Team