Types of leveling machines and their applications

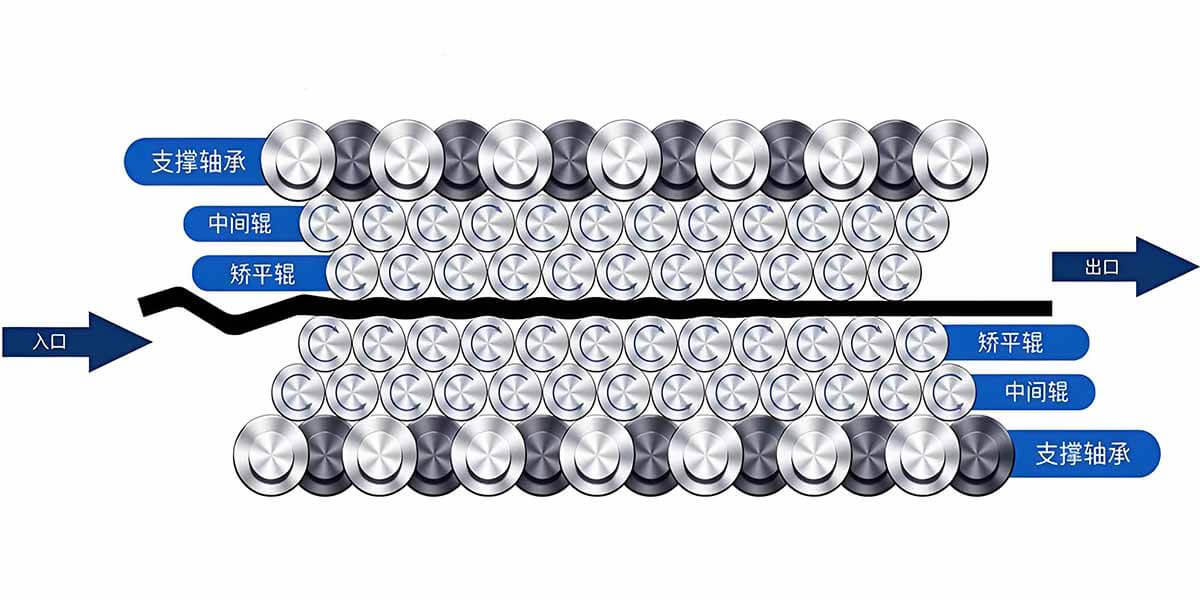

Leveling machines come in various forms, each serving a unique purpose. Precision levelers are designed for thin and delicate materials. They ensure high accuracy and are ideal for sensitive applications.

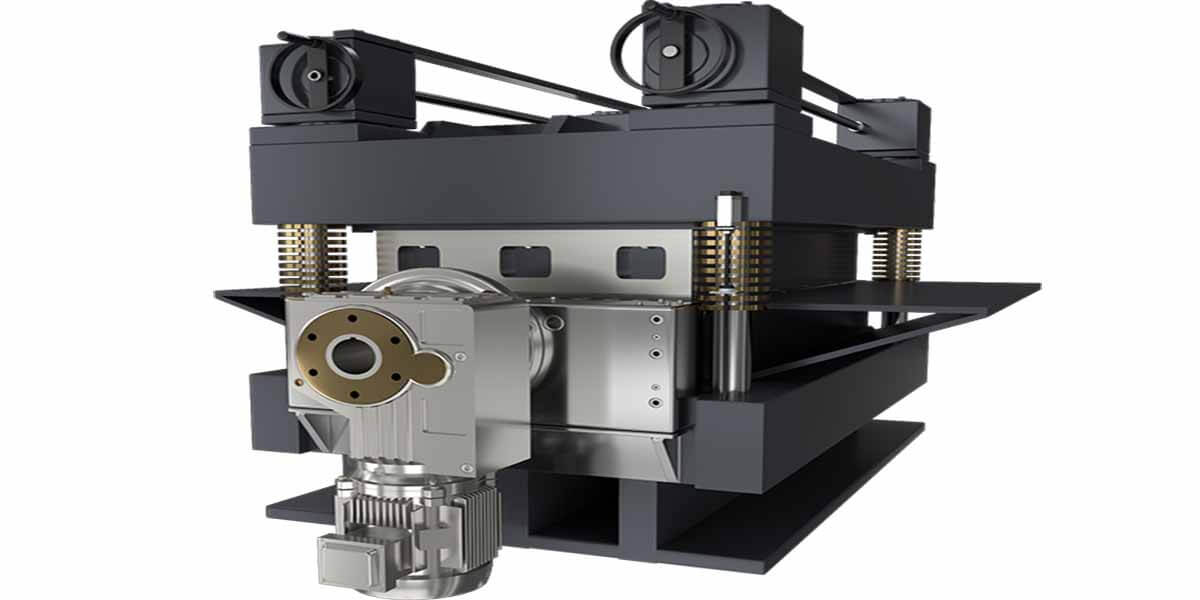

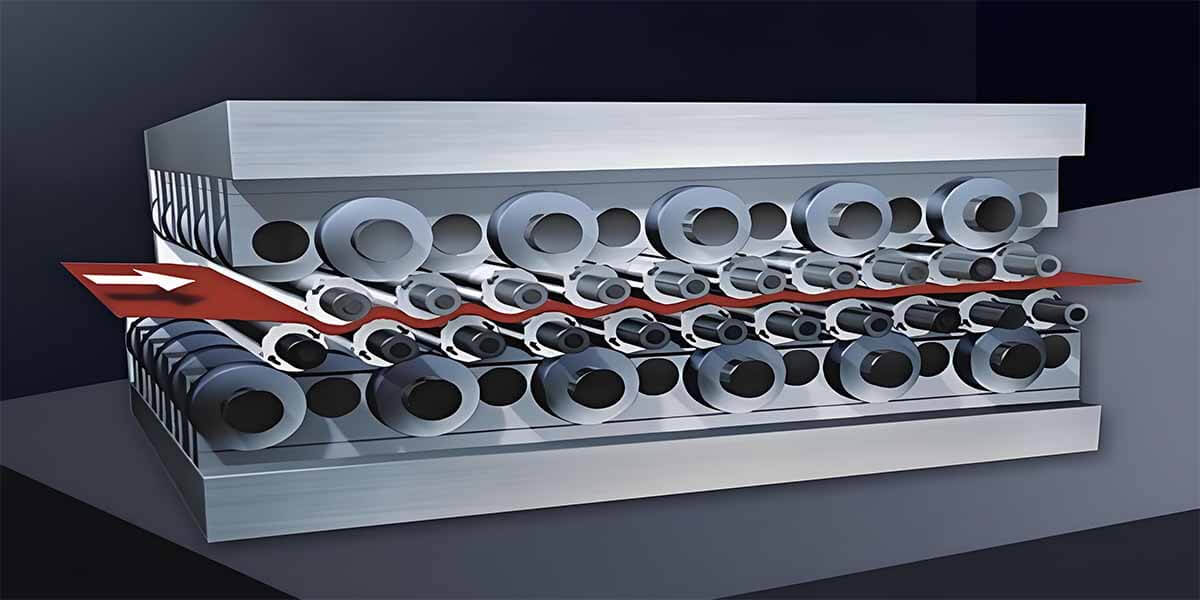

Roller levelers, on the other hand, are robust. They handle thicker, more substantial metal sheets. This makes them suitable for heavy-duty industrial tasks.

Some machines offer hybrid solutions. These combine features of both precision and roller levelers. This versatility is essential for facilities handling diverse materials.

Each type plays a vital role in specific industries:

- Precision levelers: Ideal for aerospace and electronics

- Roller levelers: Common in automotive and construction

- Hybrid levelers: Versatile choice for mixed-use production lines

Considerations for choosing the right machine depend on the material and industry requirements. Understanding these tools ensures optimal results. The right machine can boost efficiency and product quality significantly.

Key benefits of using a leveling machine for sheet metal

Using a leveling machine offers a variety of benefits that enhance metal fabrication processes. One of the primary advantages is the ability to achieve perfectly flat sheet metal. This flatness is crucial for high-quality assemblies and subsequent manufacturing steps.

Another significant benefit is the reduction in material waste. By correcting imperfections early, these machines decrease the need for rework, conserving materials and time. As a result, overall production efficiency increases.

Furthermore, leveling machines contribute to improved structural integrity and aesthetics of metal products. Their precision helps ensure consistency in thickness and flatness. These machines play a pivotal role in quality control and customer satisfaction.

Key benefits include:

- Enhanced flatness and consistency

- Reduced material waste and rework

- Improved product aesthetics and quality

Investing in a leveling machine can transform your fabrication process, offering long-term savings and superior results.

Choosing the right leveling machine for your needs

Selecting a leveling machine depends on various factors tailored to your specific requirements. Firstly, consider the type and thickness of the sheet metal you work with regularly. Different machines cater to varying thickness levels and material types.

Next, assess the scale of your operations. Smaller workshops may prefer compact machines, while industrial facilities might need larger, more robust options. Balancing capacity with space and budget constraints is key.

Additionally, explore features such as automation and precision controls. Advanced models offer real time adjustments and data analysis, elevating productivity. Weigh the need for these features against your production goals.

Consider the following factors:

- Material type and thickness

- Scale of operation

- Automation and precision features

Selecting the right machine ensures efficient processing and superior quality outcomes.

Maintenance and best practices for optimal performance

Proper maintenance is crucial to keep your leveling machine running smoothly and efficiently. Regular inspection can prevent unexpected breakdowns and extend the machine’s lifespan. It’s vital to check for wear and tear on components and to replace them as needed.

Implementing a maintenance schedule helps in identifying potential issues early. This proactive approach minimizes downtime and ensures consistent quality in your sheet metal processing tasks. Always follow manufacturer guidelines for optimal results.

Key maintenance practices include:

- Regular component inspection

- Scheduled lubrication and cleaning

- Calibration checks for precision

The future of sheet metal tools and leveling technology

The evolution of sheet metal tools and leveling technology shows no signs of slowing. Enhanced automation and digital integration are on the horizon. These advancements promise increased precision and efficiency in metal processing operations.

Environmentally friendly solutions are also gaining momentum. Manufacturers are developing machines that minimize waste and reduce energy consumption. Staying current with these innovations will ensure that your metalworking facility remains competitive in an ever-evolving industry landscape.

Conclusion

Incorporating a leveling machine for sheet metal elevates production quality and efficiency. Staying informed on advanced technologies ensures that facilities remain competitive while meeting high industry standards. Investing in these machines promises substantial long-term returns and operational improvements.

Frequently Asked Questions

Q1. What is the purpose of a sheet metal leveling machine?

A sheet metal leveling machine eliminates flatness defects in metal sheets, ensuring smooth, uniform, and high-quality surfaces that improve assembly accuracy and product performance.

Q2. What are the different types of sheet metal leveling machines?

The main types include precision levelers, roller levelers, and hybrid levelers. Precision levelers handle thin materials, roller levelers manage thicker sheets, and hybrid models combine both for versatile production needs.

Q3. What are the key benefits of using a leveling machine in metal fabrication?

Leveling machines provide perfectly flat sheets, reduce material waste, minimize rework, and enhance the overall quality and consistency of finished metal products.

Q4. How can I choose the right sheet metal leveling machine for my application?

When selecting a leveling machine, consider material type and thickness, production scale, available space, and automation features. Matching these factors ensures efficiency and long-term reliability.

Q5. How do you maintain a sheet metal leveling machine for optimal performance?

Perform regular inspections, lubricate components, clean rollers, and check calibration. Following a preventive maintenance schedule helps reduce downtime and extend machine lifespan.