Reasons why coiled material needs a plate leveling machine

Magnetic Field Uniformity:

Coils, such as those in electromagnetic devices or sensors, generate magnetic fields. If a coil is not level, the magnetic field it produces may become asymmetrical or distorted. This non-uniformity can lead to inaccurate readings in sensors, improper functioning of electromagnetic equipment, or reduced efficiency in applications like motors or transformers.

Reduction of Measurement Errors:

In precision instruments like metal detectors or magnetic resonance imaging (MRI) machines, even slight tilts in coils can introduce errors. For example, in metal detection, an unlevel coil may produce false signals or fail to detect objects accurately. Leveling ensures that the coil operates as intended, minimizing such errors.

Alignment with Other Components:

Coils often interact with other components, such as magnets, sensors, or additional coils. If a coil is not level, it may not align properly with these components, leading to suboptimal performance or even damage. For instance, in a motor, misaligned coils can cause increased friction, wear, and reduced efficiency.

Thermal and Mechanical Stability:

During operation, coils generate heat and may experience vibrations. An unlevel coil may not distribute heat evenly, leading to hotspots that can degrade the coil’s insulation or cause mechanical stress. Leveling helps ensure even heat distribution and reduces the risk of mechanical failure.

Calibration and Consistency:

Many coils require calibration to function accurately. An unlevel coil can complicate the calibration process, as the reference plane for measurements may be inconsistent. Leveling provides a stable and consistent reference, simplifying calibration and ensuring repeatable results.

Prevention of Interference:

In systems where multiple coils are used, such as in wireless charging or induction heating, leveling ensures that the coils are properly spaced and oriented. This prevents interference between coils, which can reduce efficiency or cause malfunctions.

Experimental and Industrial Standards:

In research and industrial settings, coils must often meet specific standards for performance and safety. Leveling is a fundamental step in ensuring that coils comply with these standards, as it directly affects their operation and the accuracy of results.

A plate leveling machine for coils is essential for several reasons:

- Uniform Flatness: Coils often come with inherent curvature or distortion. A leveling machine ensures that the coils are uniformly flat, which is crucial for downstream processes.

- Improved Processing: Leveling coils before further processing (such as cutting, bending, or welding) enhances the accuracy and quality of the final products, reducing the risk of defects.

- Enhanced Surface Quality: The leveling process removes any surface imperfections, ensuring a smooth finish that is vital for aesthetic and functional applications.

- Increased Efficiency: By leveling coils, manufacturers can streamline their production processes, reducing the time and effort required for manual adjustments during subsequent operations.

- Reduced Waste: Properly leveled coils minimize the likelihood of defects, which can lead to material waste. This efficiency translates to cost savings in the long run.

- Versatility: Many leveling machines can handle various coil sizes and thicknesses, making them suitable for diverse applications across different industries.

- Consistency: Automated leveling ensures consistent results across batches, which is critical to preserving quality control in manufacturing.

- Cost-Effectiveness: Investing in a plate leveling machine can lead to long-term savings by improving product quality, reducing labor costs, and minimizing waste.

A plate leveling machine for coils is a valuable investment for manufacturers looking to enhance their production efficiency, product quality, and overall operational effectiveness.

Problems Caused by Unleveled Coils

Unleveled coils can create many hidden problems in production:

Inconsistent magnetic performance in motors and transformers

Incorrect readings in testing or inspection systems

Poor alignment during assembly, which later affects processes like Precision parts deburring machine operations

Increased vibration, noise, and wear

Higher scrap rate and rework

These issues may look small at first, but over time they increase maintenance costs and reduce overall efficiency.

How Coil Leveling Helps Daily Production

When coils are properly leveled, daily factory work becomes much smoother:

Material feeds evenly into machines

Fewer manual adjustments are required

Production speed becomes more stable

Finished parts show better consistency

When coils are processed through a Cut-to-Length Line, good leveling ensures accurate cutting length, neat stacking, and fewer rejected sheets, which directly improves productivity.

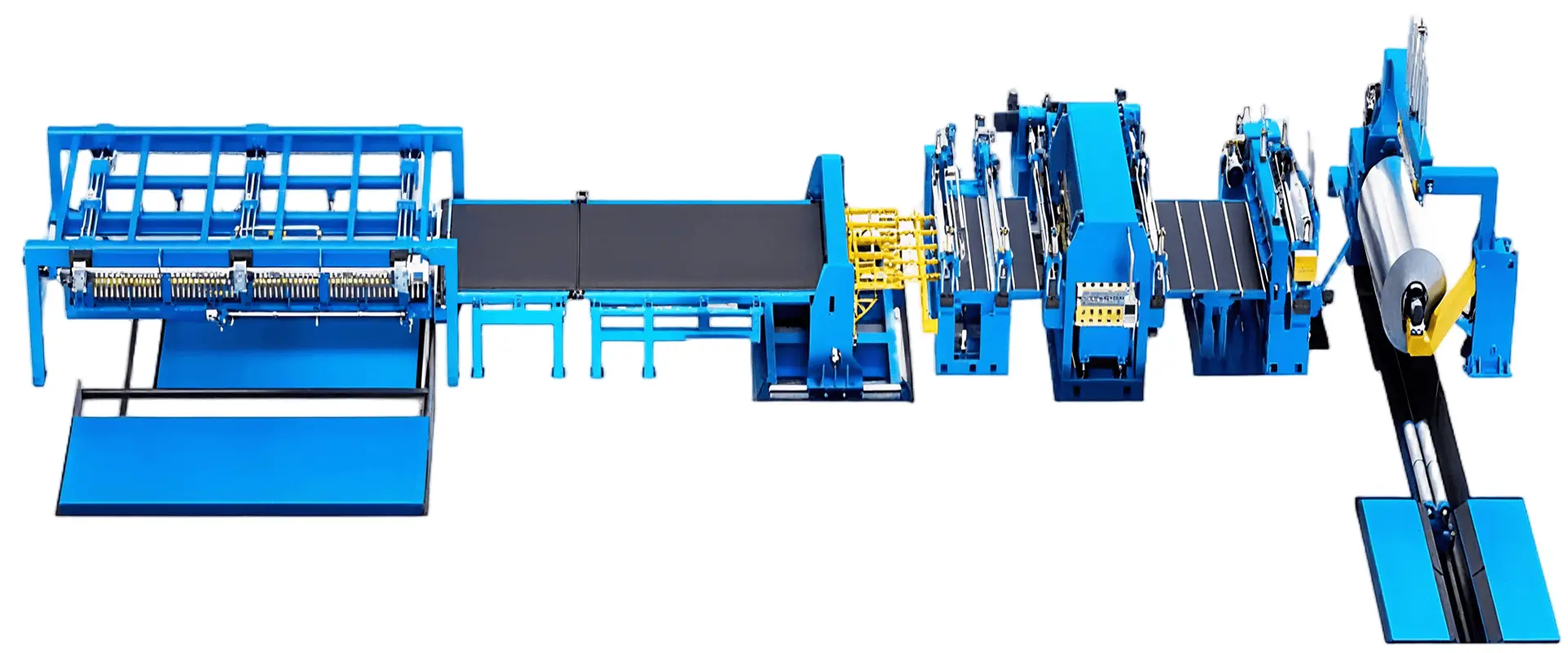

What a Plate Leveling Machine Does

A plate leveling machine for coils works by bending the material back and forth through multiple rollers. This controlled bending releases internal stress and allows the metal to settle into a flat shape. After leveling, the coil becomes easier to handle and more reliable for further processing.

Key Features Manufacturers Look For

When choosing a leveling solution, manufacturers usually focus on practical features that support long-term production:

Strong machine frame for stable operation

Adjustable rollers to handle different thicknesses

Consistent leveling accuracy across the full width

Easy operation and maintenance

Long service life under continuous use

These features help ensure stable output and reduce unexpected downtime.

Working with Other Production Equipment

In real production lines, leveling machines are part of a complete workflow. After leveling, material is commonly sent to:

Cutting and stacking systems for sheet preparation

Forming equipment such as a Hydraulic press machine

Edge-finishing equipment like a Precision parts deburring machine

When material enters these machines in a flat and stress-free condition, the entire line runs more smoothly and predictably.

Frequently Asked Questions

Q1: Why should coils be leveled before further processing?

Leveling removes internal stress and shape defects, which helps prevent problems such as misalignment, inaccurate cutting, and surface damage later in production.

Q2: Can leveling reduce material waste?

Yes. By correcting shape issues at the beginning, manufacturers can significantly reduce scrap, rework, and rejected parts.

Q3: Is leveling suitable for different coil thicknesses?

Most modern machines are designed to handle a wide range of thicknesses and materials with proper adjustment.

Q4: Does leveling improve machine life downstream?

Flat material puts less stress on cutting, forming, and finishing equipment, which helps reduce wear and maintenance costs.