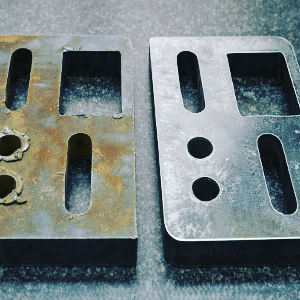

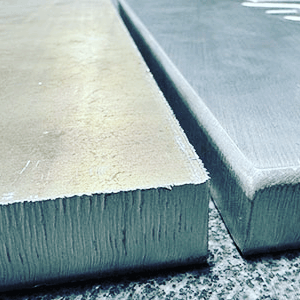

The process focuses on removing burrs, smoothing sharp edges, and refining surface finishes on metal sheets processed by laser cutting or punching. Our advanced sander machine uses high-performance, wide abrasive belts combined with flexible grinding rollers to deliver consistent and uniform finishing results. This ensures precise edge rounding and reliable surface preparation without damaging the material.

Designed for efficiency, the system reduces manual labor, minimizes dust, and improves overall workplace cleanliness. The stable conveyor mechanism supports continuous feeding and batch processing of sheets with uniform thickness. Finished workpieces are ready for bending, coating, painting, or welding with improved surface quality and reduced rework. Built for durability and reliable performance, imachine provides simple sanding solutions that enhance productivity and process modern manufacturing operations.

Designed for high-performance metal processing, this advanced sander machine delivers stable operation, consistent finishing quality, and efficient production flow. Every component is engineered to support precision, durability, and ease of use in modern manufacturing environments.

Equipped with advanced pressure regulation and servo-controlled adjustments, this high-performance sander machine ensures consistent belt contact and uniform finishing results. The automated system maintains optimal grinding pressure, improving efficiency across the entire sanding and polishing process.

Designed for long-term durability, this industrial belt sander machine features a reinforced structure and vibration-resistant frame. It delivers stable performance during continuous operation, making it suitable for demanding production environments.

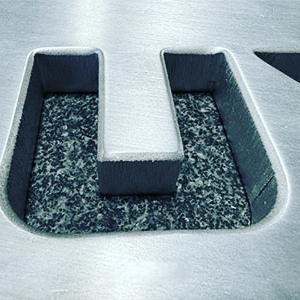

The advanced wide belt sanding machine efficiently processes different sheet thicknesses and surface conditions. It removes burrs, sharp edges, and oxidation layers while delivering smooth edge rounding for metal components.

Engineered to support precision equipment manufacturing, the system ensures consistent surface finishing before welding, coating, or assembly. It works seamlessly alongside a Deburring machine or polishing machine within integrated production lines.

Uniform abrasive consumption extends belt life and reduces downtime. Practical belt sander maintenance tips and easy-access components make servicing simple, lowering operational interruptions.

Automated feeding and rapid adjustment features increase throughput while maintaining finish quality. This makes the machine ideal for manufacturers seeking reliable edge sander performance and scalable metal finishing capacity.

As a leader in precision equipment manufacturing, Imachine designs each sander machine with a robust internal structure that ensures stability, accuracy, and long-term reliability. The system features precision-aligned rollers, a rigid frame, and a high-efficiency drive mechanism that maintain consistent belt tracking and balanced grinding pressure across the workpiece.

Flexible roller arrangements enhance belt adaptability, supporting smooth edge rounding for metal while protecting the primary surface. This optimized structure improves the overall sanding and polishing process and integrates seamlessly with a deburring machine or polishing machine in automated production lines. Reduced vibration, uniform abrasive wear, and stable performance ensure dependable finishing results even during continuous operation.

Our advanced sander machine delivers clean, precise, and consistent finishing results across various metal applications. With a high-performance wide belt sanding machine setup, burrs and sharp edges are effectively removed, improving safety, surface quality, and overall part performance. The optimized sanding and polishing process ensures uniform edge preparation while reducing manual rework and production downtime.

Designed to support precision equipment manufacturing, the system provides smooth edge rounding for metal and reliable chamfering before coating, welding, or assembly. Whether integrated with a Deburring machine or polishing machine, it enhances efficiency, surface consistency, and long-term component durability.

For product inquiries, technical details, pricing information, or customized configuration support, please contact the appropriate department. Our team will provide prompt and professional assistance based on your specific production requirements.

If you are interested in our sander machine solutions, please reach out to us for further discussion and a formal quotation.

The sander machine is suitable for carbon steel, stainless steel, aluminum, and copper. It handles various thicknesses while maintaining consistent surface quality and reliable burr removal.

A wide belt sanding machine ensures uniform pressure distribution, improving the sanding and polishing process. It delivers smooth edge rounding for metal and reduces manual finishing work.

Yes. It can operate alongside a Deburring machine or polishing machine, supporting precision equipment manufacturing and automated production lines.

Follow basic belt sander maintenance tips such as checking belt tension, cleaning rollers, and replacing worn abrasives regularly to maintain performance and extend service life.

Yes. The system functions effectively as an edge sander, providing accurate edge preparation and consistent surface finishing for industrial applications.

Would you like to request additional information about Lingyi Intelligent Machines and Engineer services?

We are happy to assist you.

Copyright © 2025 Lingyi Engineering Team