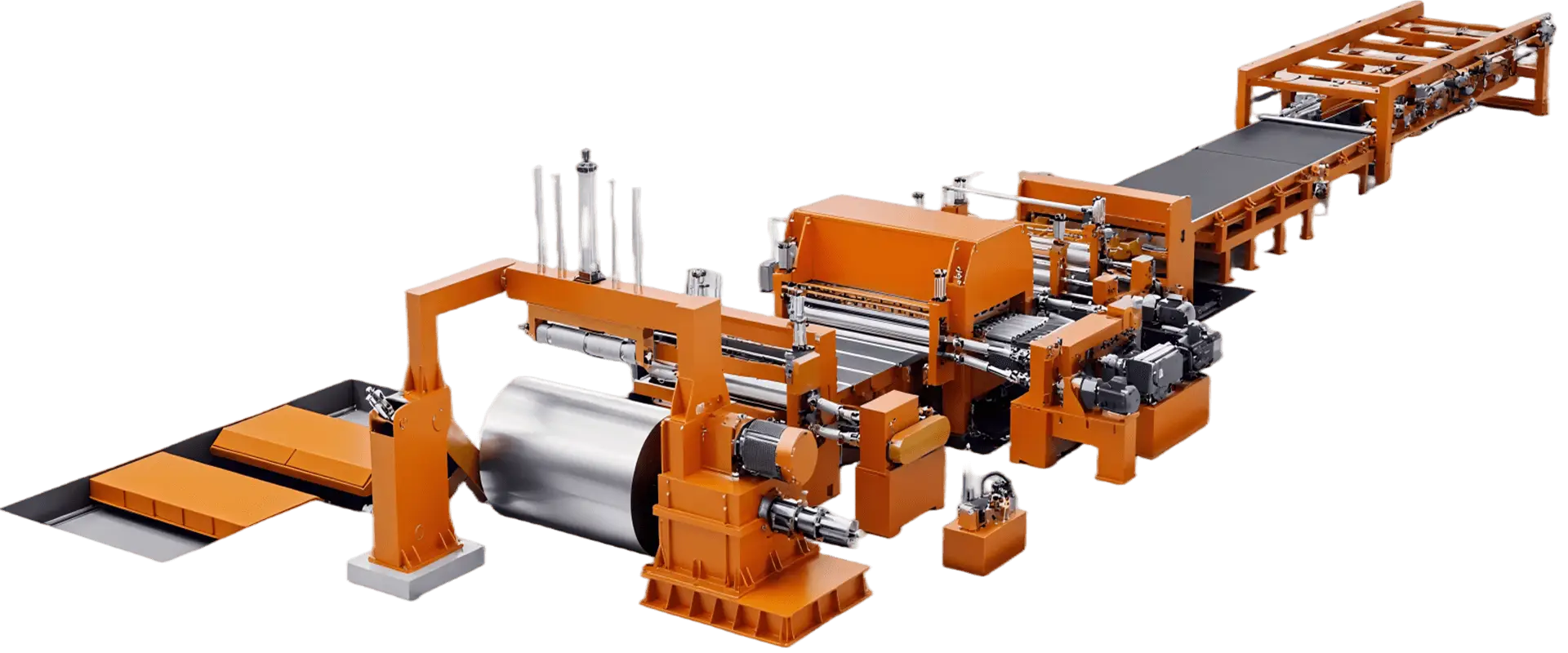

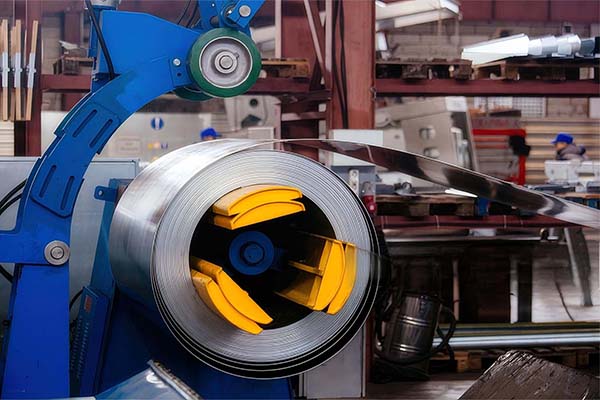

At imachine, we deliver precision and efficiency through our advanced Slitting Line Machine range, designed for modern manufacturing industries. Engineered for speed, stability, and durability, our systems ensure accurate coil cutting with minimal waste. Ideal for automotive, construction, and steel sectors, these precision machines with precision equipment redefine metal processing performance and consistency.

| Model | Thickness Range | Width (mm) | Weight | Line Speed | Scrap Winder(s) |

|---|---|---|---|---|---|

| CTL01 | 0.3–2.0mm | 1300 / 1600 | 10 / 15 / 20 | 150 m / min | Optional |

| CTL02 | 0.5–3.0mm | 1300 / 1600 | 10 / 15 / 20 | 150 m / min | Optional |

| CTL03 | 0.8–4.0mm | 1300 / 1600 | 15 / 20 / 25 | 120 m / min | Optional |

| CTL04 | 1.0–6.0mm | 1300 / 1600 | 15 / 20 / 25 | 100 m / min | Optional |

| CTL05 | 2.0–8.0mm | 1300 / 1600 | 15 / 20 / 25 | 80 m / min | Optional |

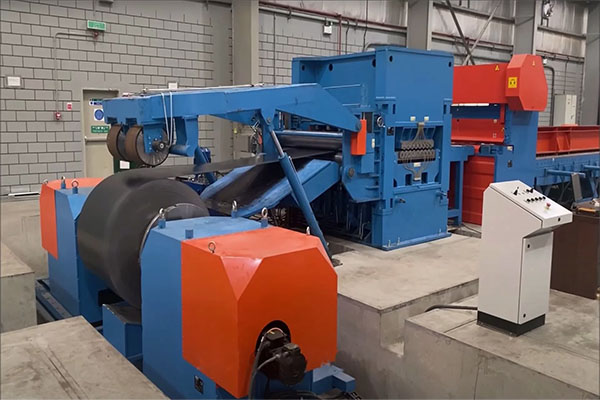

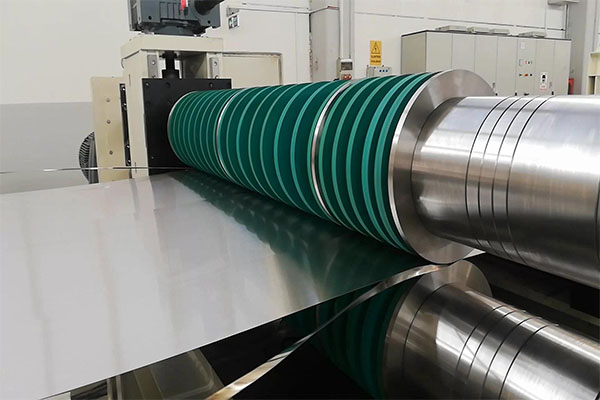

At imachine, quality meets innovation. Our steel slitting line machine range is designed to convert wide metal coils into narrow strips with remarkable consistency and precision. Every unit is built to deliver high-speed operation, stable performance, and clean cuts — all while reducing downtime and improving your overall efficiency.

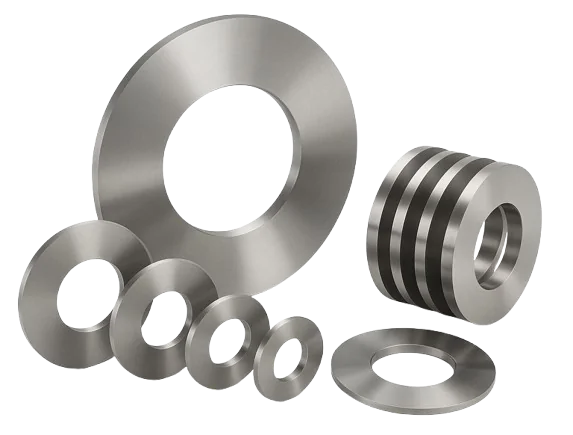

Each precision slitting machine is tailored to handle various metals, including steel, aluminum, copper, and stainless steel, making it a versatile solution for industries that demand superior output and reliable performance. These high-performance slitting line machines ensure consistent accuracy and efficiency across every production cycle.

Our slitting line manufacturers are trusted by leading companies in industries such as:

These industries rely on our cr slitting line machines for their superior cutting accuracy and fast processing capabilities. When it comes to productivity and precision, our machines are built to exceed expectations.

Boost your factory’s productivity and achieve the highest precision with our hr slitting line machines — built for performance, reliability, and long-term value. Our high-efficiency slitting production line designs ensure you stay competitive in the fast-evolving manufacturing industry.

Experience High-Performance Slitting. Precision Every Cut.

Contact imachine today to get your customized Slitting Line Machine and transform your production efficiency with world-class metal processing technology.

Our machines can process a wide range of metals, including steel, aluminum, copper, and stainless steel, with high precision and consistency, making them ideal metal slitting line machines for demanding industrial applications.

By offering automatic coil handling, precision slit width control, and high-speed operation, it reduces downtime and increases output without compromising quality.

Absolutely. We offer tailor-made configurations based on your specific material thickness, coil width, and production volume.

We provide installation, operator training, technical support, and regular maintenance checks to ensure your mechanical press machine and other equipment run smoothly throughout their lifespan.

Would you like to request additional information about Lingyi Intelligent Machines and Engineer services?

We are happy to assist you.

Copyright © 2025 Lingyi Engineering Team