Uncoiling Success: Plate straightening machine is vital for coil manufacturing.

In the world of metal fabrication, precision is not just a goal—it’s a fundamental requirement. From automotive bodies to HVAC ducting, the quality of the final product hinges on the accuracy of the raw material. For manufacturers working with metal coils, this journey to precision begins with a crucial, and often overlooked, piece of equipment: the plate straightening machines.

While a coiled sheet of metal may look perfectly smooth, it carries a legacy of stress and deformation from the coiling process. These internal stresses, known as “coil set” and “crossbow,” can wreak havoc on downstream operations. If materials aren’t properly straightened, they’ll naturally curl or buckle, triggering a series of issues.

Why Plate Straightening Machines Are Essential

Even if a coiled sheet of metal looks smooth, it often carries hidden stresses from the coiling process—known as “coil set” and “crossbow.” These internal stresses can cause sheets to curl or buckle during cutting, bending, or forming, leading to production delays and wasted material.

Using reliable Leveller equipment helps relieve these stresses, producing consistently flat sheets and preventing problems further down the line. In short, it ensures your metal fabrication workflow is efficient and your final products meet high standards.

How Plate Straightening Machines Work

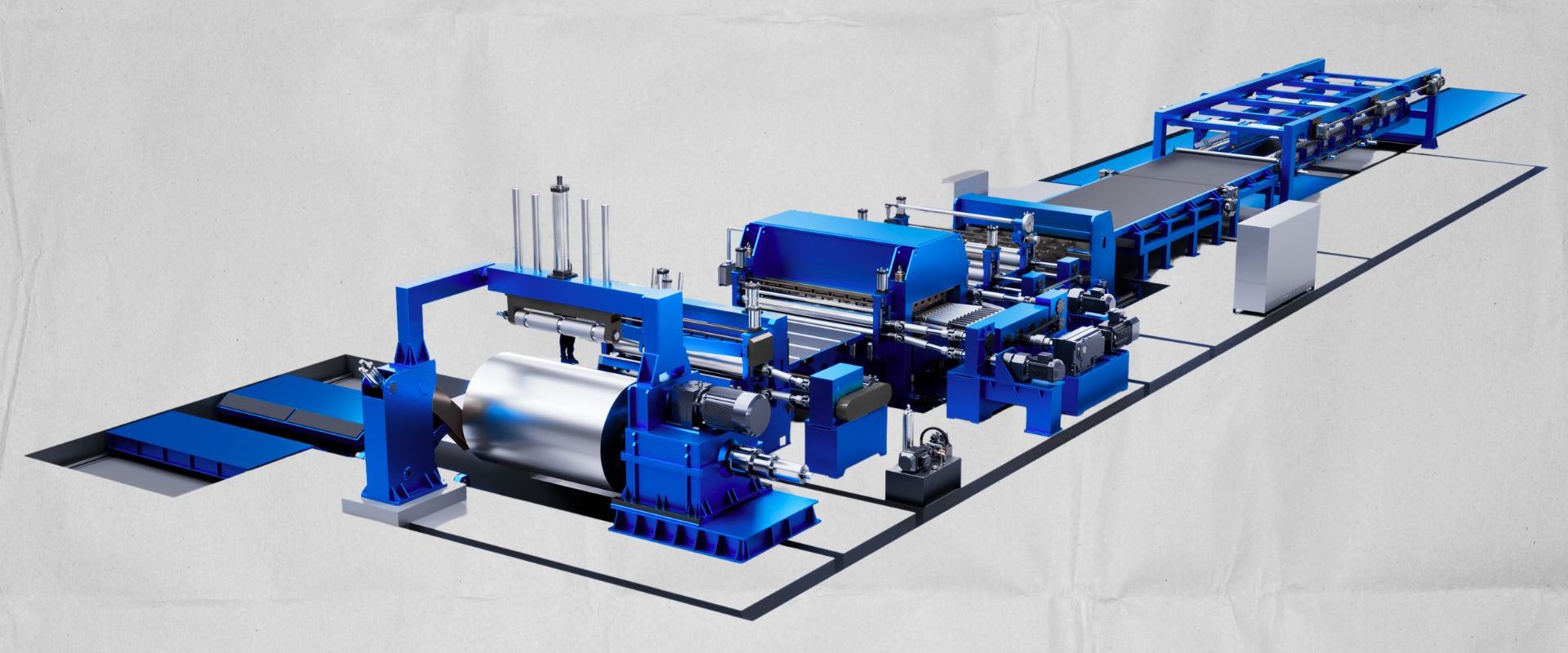

Plate straightening machines work by uncoiling coiled material, passing it through precisely spaced rollers that apply controlled bending forces to plastically deform and relieve internal stresses, resulting in a perfectly flat, stress-free metal sheet ready for further production. In the fiercely competitive realm of modern manufacturing, every minute detail holds immense significance.

Key Benefits of Using Plate Straightening Machines

- Produces stress-free, flat metal sheets for accurate downstream processing

- Reduces material waste caused by curling or buckling

- Improves efficiency and reduces manual handling

- Essential for high-precision industries and precision equipment manufacturing

- Compatible with various metals, including steel, aluminum, and copper

Frequently Asked Questions

Q1: What metals can plate straightening machines handle?

A: They are suitable for steel, aluminum, copper, and other metals commonly used in precision equipment manufacturing.

Q2: How does Leveller equipment improve the straightening process?

A: Leveller equipment automates the flattening process, delivering consistent results with less manual effort compared to traditional methods.

Q3: Can thick metal plates be straightened with these machines?

A: Yes, modern machines can handle both thin sheets and thicker plates, relieving internal stresses effectively.

Q4: How do I maintain a plate straightening machine?

A: Regular maintenance includes checking roller alignment, lubrication, and inspecting for wear. Proper care ensures long-term precision and reliability.

Q5: Why is straightened metal important in precision equipment manufacturing?

A: Flat, stress-free sheets provide a stable base for downstream operations like cutting, bending, and assembly, ensuring high-quality finished products.